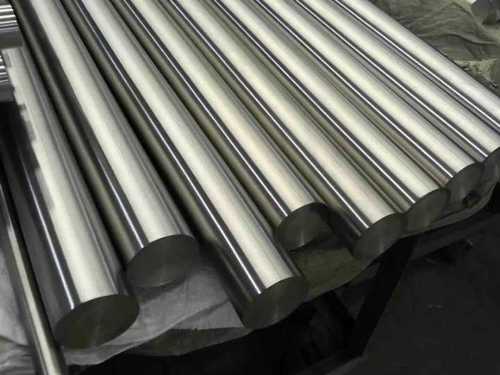

Titanium Flanges

Price 1500.00 INR/ Kilograms

Titanium Flanges Specification

- Hardness

- Rockwell

- Thickness

- 6.35 - 300mm Millimeter (mm)

- Product Type

- Titanium Flanges

- Types of Alloy

- Titanium Alloys

- Material

- Titanium

- Shape

- Round

- Melting Point

- 1668 C

- Density

- 4.507 g/cm Gram per cubic centimeter(g/cm3)

- Color

- Silver

Titanium Flanges Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Supply Ability

- 500 Kilograms Per Day

- Delivery Time

- 3-4 Days

About Titanium Flanges

FAQs of Titanium Flanges:

Q: What makes Titanium Flanges durable?

A: Their construction using titanium alloys, coupled with high Rockwell hardness, ensures resistance to wear, deformation, and environmental stress.Q: Can Titanium Flanges handle high-temperature applications?

A: Yes, with a melting point of 1668C, these flanges are well-suited for high-temperature conditions.Q: What is the thickness range available for Titanium Flanges?

A: These flanges are available in thicknesses ranging from 6.35 mm to 300 mm.Q: Are Titanium Flanges lightweight despite their strength?

A: Yes, with a density of 4.507 g/cm, they offer both lightweight properties and robust performance.Q: What industries typically use Titanium Flanges?

A: Titanium Flanges are widely utilized in aerospace, oil & gas, and chemical processing industries due to their reliability and corrosion resistance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Titanium Products Category

CP Titanium Grade 5 (Ti6Al4V)

Price 20 - 50 USD ($) / Kilograms

Minimum Order Quantity : 30 Kilograms

Shape : Other, Round / Rod / Bar

Product Type : Titanium Alloy Bar

Types of Alloy : Other, AlphaBeta Alloy

Density : 4.43 Gram per cubic centimeter(g/cm3)

Grade 23 (Ti6Al4V ELI)

Price 40.0 USD ($) / Kilograms

Minimum Order Quantity : 1 Kilograms

Shape : Bar

Product Type : Other

Types of Alloy : Titanium Alloys

Density : 4.43 Kilogram per cubic meter (kg/m3)

Titanium Grade 5 Round Bar

Price 1700 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Shape : Bar

Product Type : TITANIUM ALLOY

Types of Alloy : Titanium Alloys

Density : 4.5 Gram per cubic meter (g/m3)

UNS R56400 Ti6Al4V Titanium Grade 5 Wire

Price 4000 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Shape : Wire

Product Type : TITANIUM ALLOY

Types of Alloy : Titanium Alloys

Density : 4.5 Gram per cubic meter (g/m3)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free