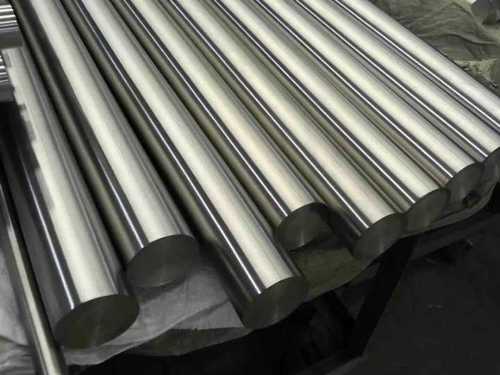

Inconel Wires

Price 40.0 USD ($)/ Kilograms

Inconel Wires Specification

- Thickness

- 3-4 mm Millimeter (mm)

- Hardness

- Other

- Types of Alloy

- Inconel

- Material

- Inconel

- Shape

- Round

- Grade

- 718

- Color

- Silver

Inconel Wires Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Supply Ability

- 1 Kilograms Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- As per client requirement

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Central America, Africa, South America, Western Europe, Asia, North America

About Inconel Wires

Inconel Wires

GRADES AVAILABLE : INCONEL 600, INCONEL 601 INCONEL 617, INCONEL 625, INCONEL 718, INCONEL X750, INCONEL 800/800H/800HT, INCONEL 825, INCONEL 925

Product Details

|

Diameter |

0.13 - 12 mm |

|

Usage/Application |

Industrial |

|

Material |

Inconel |

|

Packaging Type |

Roll |

|

Grade |

825 |

Premium Alloy for High-Temperature Applications

Inconel wires, specifically in grade 718, exhibit remarkable durability under intense heat and corrosion. Their resilience ensures longevity and minimal maintenance in fields such as aerospace and chemical plants. The round shape and 3-4 mm thickness make these wires versatile for varying technical requirements.

Expert Distribution and Export Network

As a distributor, exporter, manufacturer, supplier, and trader based in India, our operations ensure a consistent supply chain for Inconel round wires. Our commitment to timely delivery and adherence to industry standards has established us as a reliable partner for domestic and international clients.

FAQs of Inconel Wires:

Q: How are Inconel round wires with 3-4 mm thickness typically used in industry?

A: These wires are primarily used in high-stress and high-temperature environments, such as in turbines, heat exchangers, and chemical processing equipment. Their ability to withstand extreme conditions makes them ideal for critical industrial components.Q: What is the manufacturing process for Inconel grade 718 round wires?

A: Inconel wires are produced by melting and alloying raw materials, followed by hot and cold working processes to achieve the desired 3-4 mm thickness and round shape. Strict quality controls ensure the material meets required specifications.Q: When should I choose Inconel 718 wires over conventional materials?

A: You should select Inconel 718 wires for applications involving high temperatures, corrosive environments, or where mechanical strength retention is vital. They outperform conventional metals in scenarios requiring exceptional toughness and reliability.Q: Where can I source Inconel 718 round wires in India?

A: Inconel 718 round wires are available from various distributors, exporters, manufacturers, suppliers, and traders across India. Our network ensures accessibility for clients requiring bulk or specialized orders.Q: What are the benefits of using Inconel 718 round wires?

A: Inconel 718 wires offer excellent resistance to corrosion and oxidation, high tensile strength, and stability at elevated temperatures. This results in reduced downtime and longer service life in critical installations.Q: How is the quality of Inconel round wires ensured during manufacturing?

A: Quality assurance involves rigorous testing for mechanical strength, chemical composition, and surface finish. Each batch undergoes inspection to ensure compliance with industrial standards and customer requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inconel Alloy Products Category

Inconel 800H Round Bar

Price 1100 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Density : 8.14 Gram per cubic meter (g/m3)

Grade : UNS N08810 INCOLOY 800H

Shape : Bar

Application : Construction, Fastener, Chemical, Welding Material, Military, Nuclear, Other , Valve, Petroleum

Inconel 825 Wires

Price 1500 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Density : 8.14 Gram per cubic meter (g/m3)

Grade : UNS N08825 INCONEL 825

Shape : Wire

Application : Valve, Fastener, Petroleum, Chemical, Construction, Military, Nuclear

Inconel 925 Round Bar

Price 1100 INR

Minimum Order Quantity : 1 Kilograms

Density : 8.14 Gram per cubic meter (g/m3)

Grade : UNS N09925 INCOLOY 925

Shape : Bar

Application : Valve, Fastener, Petroleum, Chemical, Construction, Oil & Gas, Military, Nuclear, Other

INCONEL 800H PLATE

Price 1000 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Density : 8.5 Kilogram per cubic meter (kg/m3)

Grade : Incoloy 800 / 800H / 800HT

Shape : Pipe, Bar, Plate, Stripe, Wire

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free