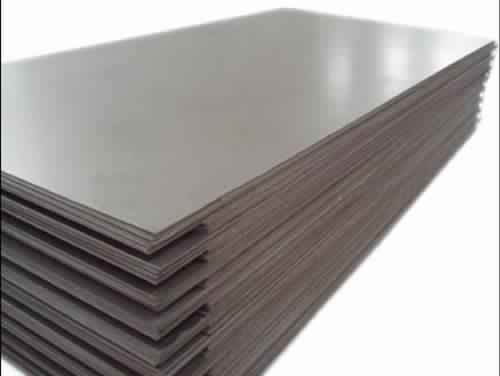

Nimonic 900 Plates

Price 2000.00 INR/ Kilograms

Nimonic 900 Plates Specification

- Product Type

- Nickel Alloy

- Shape

- Plate

- Strength

- 140 - 200 (MPa)

- Hardness

- 35 - 45 HRC

- Grade

- NImonic 90

- Density

- 8.06 Kilogram per cubic meter (kg/m3)

- Application

- Tungsten Sheet

- Color

- Silver

Nimonic 900 Plates Trade Information

- Minimum Order Quantity

- 1 Kilograms

- FOB Port

- NHAVA SHEVA

- Supply Ability

- 1000 Kilograms Per Week

- Delivery Time

- 2 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- EXPORT QUALITY

- Main Export Market(s)

- Australia, Central America, Middle East, North America, Western Europe, Africa, South America, Asia, Eastern Europe

- Main Domestic Market

- All India

- Certifications

- 3.1 MTC

About Nimonic 900 Plates

FAQs of Nimonic 900 Plates:

Q: What are the key properties of Nimonic 900 Plates?

A: Nimonic 900 Plates feature high durability, a silver finish, a density of 8.06 kg/m, 35-45 HRC hardness, and tensile strength of 140-200 MPa.Q: What industries commonly use these plates?

A: They are primarily used for tungsten sheet production and other industrial applications requiring strength and heat resistance.Q: What grade material is used for Nimonic 900 Plates?

A: They are made from high-quality Nimonic 90 material.Q: How do these plates perform in high-stress environments?

A: They offer excellent performance due to their superior tensile strength and wear resistance.Q: What is the shape availability of Nimonic 900 Plates?

A: These plates are provided in versatile rectangular shapes suited for various industrial uses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Nimonic Products Category

Nimonic 80A Plates

Price 2000.00 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Product Type : Nickel Alloy

Grade : Nickel Alloy 80A

Hardness : 60 75

Density : 8.06 Gram per cubic centimeter(g/cm3)

Nimonic 750 Plates

Price 2000.00 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Product Type : Nickel Alloy

Grade : NIMONIC 75

Hardness : 60 75

Density : 8.5 Kilogram per cubic meter (kg/m3)

Nimonic Round Bar

Price 1000 INR

Minimum Order Quantity : 1 Kilograms

Product Type : Other, Nimonic Round Bar

Grade : Nimonic 80A / Nimonic 90 / Nimonic 75 (as per requirement)

Hardness : 200250 HB

Density : 8.2 Gram per cubic centimeter(g/cm3)

Nimonic Sheets

Price 2000 INR

Minimum Order Quantity : 1 Kilograms

Product Type : Other, Nimonic Sheets

Grade : Nimonic 75, Nimonic 80A, Nimonic 90

Hardness : 190250 HB

Density : 8.2 Gram per cubic centimeter(g/cm3)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS